Rendered at 11:12:20 07/25/25

220V Three-Roll Grinder Ointment Mill Crushing,Lab Dispersion Grinding Machine

$809.00

Shipping options

Estimated to arrive by Mon, Aug 4th.

Details

$110.00 via Standard shipping (1 to 5 business days) to United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Refunds available: See booth/item description for details

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Shipping options

Estimated to arrive by Mon, Aug 4th.

Details

$110.00 via Standard shipping (1 to 5 business days) to United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Refunds available: See booth/item description for details

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Item traits

| Category: | |

|---|---|

| Quantity Available: |

Only one in stock, order soon |

| Condition: |

New |

| MPN: |

134121 |

| UPC: |

748497573545 |

Listing details

| Seller policies: | |

|---|---|

| Shipping discount: |

Items after first shipped each discounted 0.0% |

| Posted for sale: |

More than a week ago |

| Item number: |

1312704304 |

Item description

Laboratory Three Roll Grinding Mill Grinder For Lab Applicationsb

Performance feature

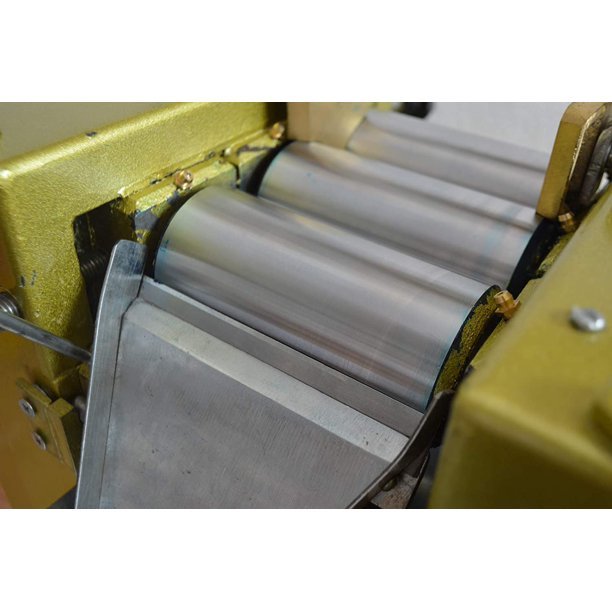

The machine is mainly used to grind various paint, ink, paint pigments, paints, food, cosmetics and other paste materials. The machine has become the main equipment of abrasive material.

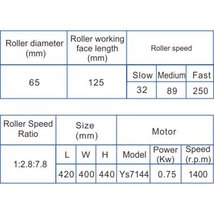

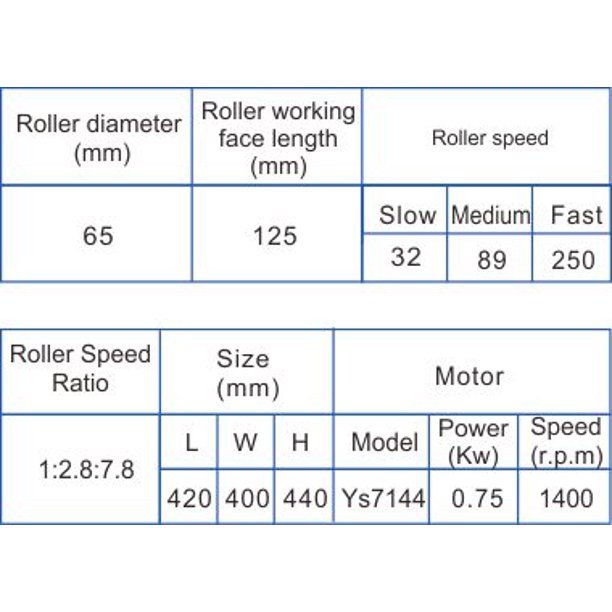

Three rollers of the machine with chilled alloy casting, thickness of chilled alloy layer is 15 - 25 mm, surface hardness is HS68 ~ 75. After grinding for once or several times, finally achieve the required fineness (about 3 to 18 microns in general, to fineness determination).

Three-roll mill consists of seat, the guide cover, the roll shaft housing, feeding copper knife, the riving knife plate, the cooling means and gears, pulleys, etc.

1.Machine construction

(1) Transmission systems

(2) Moving parts

(3) The roller

(4) Loading parts

Maintly consists of two copper knife and copper knife holder. Prevent grind maerial to both ends overflow. (5) Cooling parts

(6) Adjustment parts

(7) Discharging device

By adjusting the pressure screw on the blade, the incision should be slightly higher than the center of the roll,this makes it easy scraped the materials attached to the roller surface .

2.Note:

2.1 Before work:

Keep the roller surface clean, lubrication part has enough lube

2.2 At work:

(1) After start the machine, adjust fast, slow roll to a certain position (soap and lead ,the distance of fast, slow roll is 0.5 mm or so).According to your need to make a precise regulation after add materials. Generally ,the colorific deepness is consistent after the roller adjust well .If the middle colour is light but two ends colour are thick ,you can adjust the speed of the cooling water .

(2) Avoid grinding with corrosive materials.

(3)Charging copper knife can't press too hard.Add lubricant in the contact arc frequently.

(4) Pay attention to the bearing, it's temperature should not be higher than 45 ?.

2.3 After work

Loosen the roller, copper knife blade and discharge, then clean it .

3.Maintenance and repair

(1) Please inject lubricating oil on the roller left every 3~5 days .

(2) We have inject enough lubricating oil to the bearing house .Please inject lubricating oil half years later. (3) If long term storage ,please coated the rollers and other moving parts with preservative grease .

(4) Please stop use the machine if the rollers out of shape(both ends are low, and the middle is high), then repolished and adjust .

Manual

Added to your wish list!

- 220V Three-Roll Grinder Ointment Mill Crushing,Lab Dispersion Grinding Machine

- 1 in stock

- Price negotiable

- Handling time 3 days. Estimated delivery: Mon, Aug 4th

- Returns/refunds accepted

Get an item reminder

We'll email you a link to your item now and follow up with a single reminder (if you'd like one). That's it! No spam, no hassle.

Already have an account?

Log in and add this item to your wish list.